charpy impact test plain strain|charpy impact test pdf : specialty store Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM WEB15 de Fevereiro de 2024 - Ano 10. NOTÍCIAS. Editoria: Bizarro. Mulher quebra recorde mundial de unhas mais longas. Homem considerado morto aparece vivo meses depois .

{plog:ftitle_list}

A lua de hoje está 91,65% visível e está decrescendo. Falta.

charpy impact test sample

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTMIn materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

charpy impact test procedure

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .

The widely used Charpy impact test is a standard way to assess toughness quantitatively in notched specimens. In this test a standard bar specimen, with a square cross section and a V .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .

Impact Tests. Impact tests are designed to measure the resistance to failure of a material to a suddenly applied force. The test measures the impact energy, or the energy absorbed prior to fracture. The most common .Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of metals. It is a standardised high strain-rate test that can measure the amount of .

This study addresses the correlation between the ductile-to-brittle transition temperature ranges of high strength 4140 steel obtained respectively from tensile tests under plane strain (PS) .

charpy impact test pdf

This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen . Afterward, Charpy impact energy of each constituent layer was assumed to be proportional to the area under modified stress–strain curve and Charpy impact energy of the functionally graded . However, the plane strain fracture toughness (K IC) test is much too complex and conduct strictly, . Fig. 3 reveals the SEM images of the specimen after Charpy impact testing. It is seen in Fig. 3 (a) that the macroscopic fracture surface can be separated into shear and flat fracture zone, . Estimation of fracture toughness (K IC) using Charpy impact test for Al6061T6 and Al7075T6 alloys subjected to corrosion. Author links open overlay panel S. Sunil Kumar a b, Neelakantha V. Londe b, K. Dilip Kumar c, . “Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness KIC of Metallic Materials”, (2017). Google Scholar

Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to . In contrast, a plane-strain fracture toughness test would have to be performed in an environmental chamber for non-ambient temperature testing. It is known that fcc materials do not undergo a DTBT, while and hcp bccWith regard to the plane strain fracture toughness, a material textbook states that: “ Attempts have been made to correlate plane strain fracture toughnesses and Charpy V-Notch energies, with only limited success. Plane strain fracture toughness tests are not as simple to perform as impact tests; furthermore, equipment and specimens are more .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. . In this plane strain geometry, plastic deformation is constrained, and low, relatively constant k 1C values are .

All these elements contribute to the differences between the Charpy impact test results and quasi-static fracture toughness data, in particular the tearing resistance responsible for the ductile crack extension occurring in the Charpy V-notch impact specimen in comparison to a plane strain 20%-side-grooved fracture toughness specimen.

Identification of ductile to brittle transition temperature by using plane strain specimen in tensile test and correlation with instrumented Charpy impact test: Experimental and numerical study

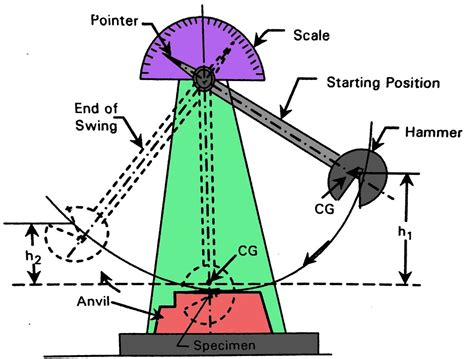

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . factors that affect the yield behaviour and hence ductility of the material such as temperature and strain rate will affect the impact . useful in the development of a standardized test method for Charpy impact testing of cementitious composites. The Charpy Test The Charpy impact test relies on the potential energy of a weighted pendulum as shown in Fig. 1. The pendulum is raised to some initial height h i, which is measured from the center of mass to the datum.Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat. Charpy V-notch (CVN) impact-test results are used widely in various toughness specifications even though the energy absorption values cannot be related directly to structural design. Conversely, K Ic , the plane-strain stress-intensity factor at onset of unstable crack growth, can be related to structural design, but K Ic test results usually .

1. Introduction. Instrumented impact testing is often considered to be a relatively recent technical development of Charpy testing, even though the earliest known paper dealing with force measurements during an impact test [] actually predates the first pendulum machine publication [] by one year.In actual fact, instrumented Charpy testing started to gain .Keywords: Martensite-bainite / carbides / Charpy test / notched plane-strain specimen / experimental and numerical study 1 Introduction High strength, quenched and tempered steels have been . Charpy impact testing is a powerful tool to study the ductile-to-brittle transition (DBT) of body-centered cubic * e-mail: frank.tioguem-teagho@mines .

Review of development in plane strain fracture toughness testing, ASTM. STP 463, ASTM; 1970. p. 124–59. [18] Barsom JM, Rolfe ST. Correlations between KIC and Charpy V-notch test results in the .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .The Charpy impact test, also known as the Charpy v-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.This absorbed energy is a measure of a given material's toughness and acts as a tool to study temperature-dependent brittle-ductile transition.were measured using Charpy V-notch impact tests, plane strain ("static") fracture toughness (KIc) tests, and dynamic fracture toughness (Kid) tests. Charpy . Charpy impact and KIc values that the higher strain rate of the impact test (~101- 102 s -1 compared to ~10 -4 s "1 in static tests) may induce a change in frac- .

refractometer conversion after fermentation

The Charpy impact test, also known as the Charpy v-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.This absorbed energy is a measure of a given material's toughness and acts as a tool to study temperature-dependent brittle-ductile transition.

Fracture toughness, as detenlned by plane-strain testing methods, has been used only to a United extent as a criterion in qualifying steels for »ili- tary applications. . sophisticated Charpy V-notch impact test» or on reduction-in-area-transverse .%PDF-1.5 %âãÏÓ 1381 0 obj > endobj 1397 0 obj >/Filter/FlateDecode/ID[99F09C433BA3E74FAFD6B5679B801655>10D0DE9B1FDC084D81D228EB77CDEE20>]/Index[1381 42]/Info 1380 .

Instrumentation of the Charpy impact test permits an analysis of the data in terms of linear elastic fraeture mechanics. Measurements of time to fracture are converted to estimated crack opening displacements at fracture and thus to values of the fracture toughness parameter KC. The variation of these values with temperature shows a transition which is interpreted as a .

charpy impact test formula

This set of Mechanical Metallurgy Multiple Choice Questions & Answers (MCQs) focuses on “Brittle Fracture and Impact Testing – Instrumented Charpy Test”. 1. Which of the following is not among the basic condition responsible for causing the fracture of brittle? a) A triaxle state of stress b) Low temperature c) High strain rate This study addresses the correlation between the ductile-to-brittle transition temperature ranges of high strength 4140 steel obtained respectively from tensile tests under plane strain (PS) conditions and from conventional Charpy impact tests. Specimens were taken respectively at 25 mm (P) and at 55 mm (M) from skin of a cylindrical 90-mm-radius hot rolled .

charpy impact test calculator

In the plane strain region, numerous dimples are generated, which can achieve high absorbed impact energy and toughness during the impact process [22, 36]. . [54]) in Charpy impact test facilitates the occurrence of phase transformation at LNT, which usually happens at 4.2 K in quasi-static tensile tests [55, 56] .Inherent in the Charpy impact test are high strain rates. These are so high, in fact, that in practice, they are representative only of ballistics‐type applications. . In real components, the plain strain condition (explained later) is often the dominate state. It is possible to impose this on Charpy specimens, though, using proper sample . In the charpy impact test we use a test specimen which have a notch at one side of it. Figure 4 — Specimen Deformation of the material is confined to a small volume and stress in concentrated .

charpy impact test calculation table

webFuteMAX – FUTEBOL – UFC – ESPORTES E MUITO MAIS, SEM ANÚNCIOS! Futmax é a plataforma perfeita para assistir futebol ao vivo de qualidade, livre dos incômodos dos .

charpy impact test plain strain|charpy impact test pdf